Research

Our laboratory aims to develop novel process technologies that can fully derive the intrinsic functions of materials by using the aerosol process or combining it with a powder technology. We also explore novel materials using our process technologies and analyze transport phenomena during the synthesis of materials. The current main focus is the development of cost-effective electrode materials with advanced functions used for lithium secondary batteries and their manufacturing techniques.

- Development of cathode materials for lithium secondary batteries

- Synthesis of functional ceramic microparticles using high-temperature fluidized bed

- Morphological control of functional ceramic thin films

- Future prospects

(Summary of research contents / Japanese version ![]() ,English version

,English version ![]() )

)

1. Development of cathode materials for lithium secondary batteries

Lithium secondary batteries have recently been attracting much attention as a high-capacity power supply. However, they have not yet become widespread because of their high manufacturing cost. Our laboratory aims to develop cost-effective, safe, and high-performance cathode materials that can be used for lithium secondary batteries.

Concrete research themes

- Synthesis of spinel lithium manganese oxide nanoparticles and nanostructured particles by spray pyrolysis and analysis of their discharge characteristics for lithium secondary battery

- Synthesis of polyanion-based cathode materials (LiMPO4; M = Fe, Mn, or Co) by spray pyrolysis and powder technology and analysis of their discharge characteristics for lithium secondary battery

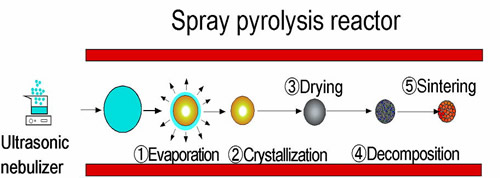

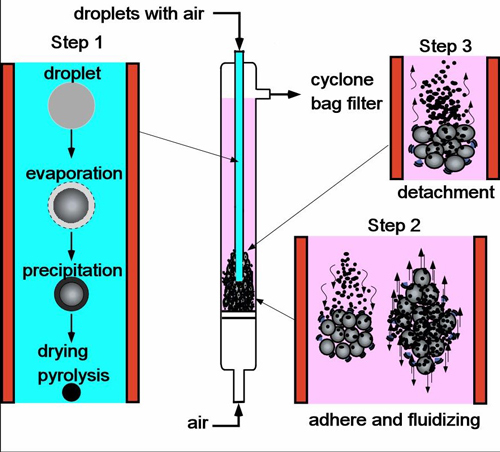

Fig. 1 Principle of synthesis of functional ceramic nanoparticles by spray pyrolysis.

Metal nitrate, acetate, and chloride used as raw materials are dissolved in distilled water at a stoichiometric ratio. The mixed solution is treated using an ultrasonic nebulizer or twin-fluid nebulizer to obtain mists with droplets of 2-30 μm diameter, which are introduced with an entrained gas into a high-temperature reactor. Because the inside of the reactor is at a high temperature, the solvent is evaporated from the surface of droplets (① in Fig. 1), and the solute is deposited or precipitated (②) to form solid particles. These particles are dried (③), thermally decomposed (④), and sintered (⑤) to obtain the target nanoparticles.

|

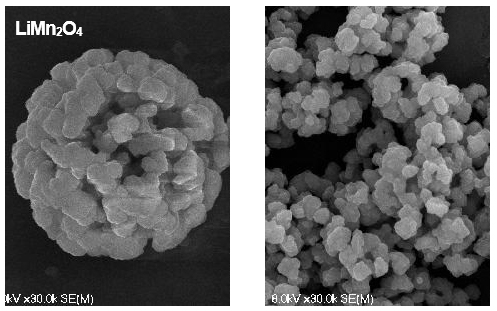

Fig. 2 Nanostructured LiMn2O4 particles and LiMn2O4 nanoparticles synthesized by spray pyrolysis.

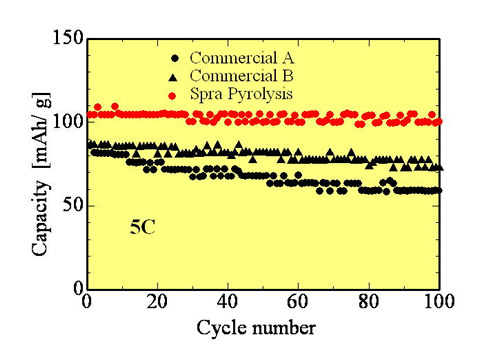

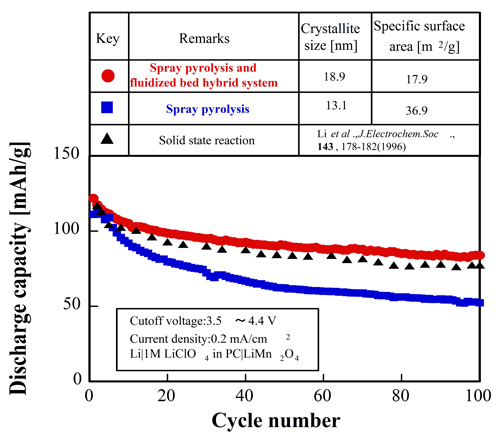

Fig. 3 Cycle perfromance of nanostructured LiMn2O4 particles synthesized by spray pyrolysis for lithium secondary battery (in comparison with those of commercial batteries).

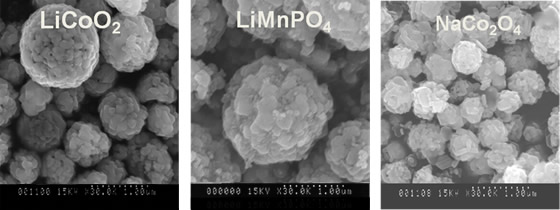

The LiMn2O4 particles synthesized by spray pyrolysis are in the form of nanostructured spherical agglomerates of primary particles with a diameter of a few nanometers (Fig. 2). LiMn2O4 particles in this form cannot be obtained by other synthesis methods. The discharge characteristics of our LiMn2O4 cathode material used for lithium secondary batteries (Fig. 3) are superior to those of commercial cathode materials in terms of both capacity and cycle number. In addition, LiMn2O4 nanoparticles (the right hand side of Fig. 2) can be synthesized by adding special salts to the precursor solution. The synthesis of other nanostructured spherical particles, as shown in Fig. 4, is also possible.

Fig. 4 Nanostructured spherical particles.

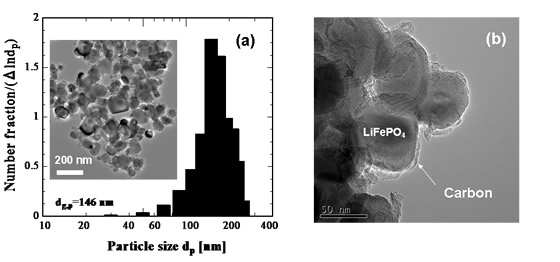

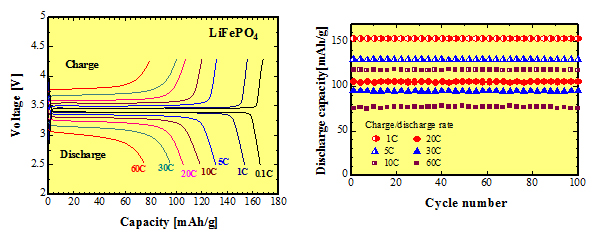

Olivine cathode materials (LiMPO4; M = Fe, Mn, or Co) had the problem of extremely low electron conductivity. We have developed a novel synthesis method of a combination of spray pyrolysis and a powder technology (ball mill) and have overcome the problem. By our synthesis method, we have successfully developed a nanostructured LiMPO4/C composite cathode material (Fig. 5). A lithium secondary battery using this cathode exhibited excellent discharge characteristics (Fig. 6). This study was part of the “Development of Electrical Storage System and Technology for Smooth Introduction of Dispersed Power Generation Systems - Development of Next-Generation Technologies” project supported by the New Energy and Industrial Technology Development Organization (NEDO) in FY 2006-2009.

Fig. 5 Nanostructured LiFePO4/C composite cathode.

Fig. 6 Battery performance of nanostructured LiFePO4/C composite cathode used for lithium secondary battery.

2. Synthesis of functional ceramic particles using high-temperature fluidized bed

Fluidized beds are the reactors that have long been used in chemical industrial processes. Our laboratory aims to synthesize functional ceramic particles by fully utilizing a fluidized bed reactor.

Concrete research themes

- Synthesis of LiMn2O4 and LiNi0.5Mn1.5O4 powders by drip pyrolysis in a fluidized bed reactor

- Synthesis of LiMxMn2-xO4 (M = Mn, Co, Al, or Fe) powders by spray pyrolysis in a fluidized bed reactor

Fig. 7 Principle of synthesis of highly crystalline functional ceramic particles using a spray pyrolysis and fluidized bed hybrid system.

The principle of the synthesis of high-crystallinity functional ceramic particles is as follows. While the aerosol of the precursor solution is passing through the inner tube of the fluidized-bed reactor heated to a high temperature, the solvent is evaporated from the surface of droplets and the solute is precipitated, dried, and thermally decomposed (the step 1 in Fig. 7) to obtain metal oxide fine particles (1-5 μm in diameter). These particles are attached to coarse particles (500 μm in diameter, inactive materials not reactive with the fine particles) that are fluidized in the reactor (the step 2 in Fig. 7) and sintered while remaining in the reactor for a certain duration (the step 2 in Fig. 7). Afterwards, the coarse particles collide with each other and the fine particles are separated from the coarse particles (the step 3 in Fig. 7) and released from the reactor.

Fig. 8 Cycle performance of LiMn2O4 particles for lithium secondary battery, synthesized by a spray pyrolysis and fluidized bed hybrid system (in comparison with conventional methods).

As is obvious from Fig. 8, we have successfully obtained, by the novel technology involving spray pyrolysis and fluidized bed reactor, ceramic particles with higher crystallinity than those obtained by conventional methods, as well as synthesized excellent materials that can be used for lithium secondary batteries. Here, the battery characteristics were evaluated using our original spring cell. (Keego Matsuda, who was a Ph.D student engaged in this research at that time and is currently an associate professor at Yamagata University, won the Society of Chemical Engineers, Japan (SCEJ) Award for Outstanding Young Researcher in FY 2008.) ![]()

3. Morphological control of functional ceramic thin films

We aim to synthesize energy-convertible and –storage thin-film materials and to study their morphological control by electrostatic spray deposition, which is a process used for synthesizing functional ceramic thin films by aerosol processes.

Concrete research themes

- Synthesis of porous LiCoO2 films by electrostatic spray deposition

- Synthesis of TiO2 thin films by electrostatic spray deposition and their application to dye-sensitized solar cells

- Synthesis of thin-film cathode materials used for solid oxide fuel cells by electrostatic spray deposition and control of film structure

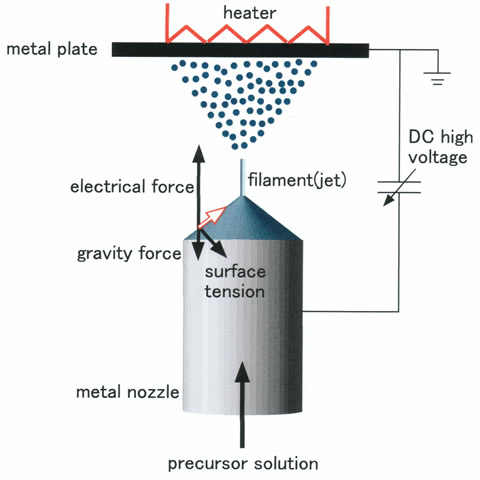

Fig. 9 Principle of synthesis of functional ceramic thin film by electrostatic spray deposition.

First, metal nitrate or chloride is dissolved into an alcohol or other solution at a stoichiometric ratio to obtain a precursor solution that is constantly supplied to a fine metallic tube (nozzle). When a high DC voltage is applied to the nozzle, an electric field is formed between the nozzle and the grounded opposing electrode. As a result, electrostatic force is newly applied to the meniscus of the solution formed at the tip of the nozzle. The meniscus is distorted into a conical shape to form a liquid filament from the tip. The filament is split into fine droplets. These droplets are efficiently deposited on a grounded substrate under the effect of Coulomb force because they are electrically charged. Therefore, functional ceramic thin films can be synthesized by heating the substrate using a heater (Fig. 9).

|

|

|

|

Fig. 10 Porous thin films synthesized by electrostatic spray deposition

(A) Electrode material for lithium secondary batteries, (B) electrode and electrolyte materials for solid oxide fuel cells, and (C) electrode material for dye-sensitized solar cells.

In electrostatic spray deposition, ceramic thin films with various surface morphologies, as shown in Fig. 10, can be synthesized by varying the deposition conditions.

4. Future prospects

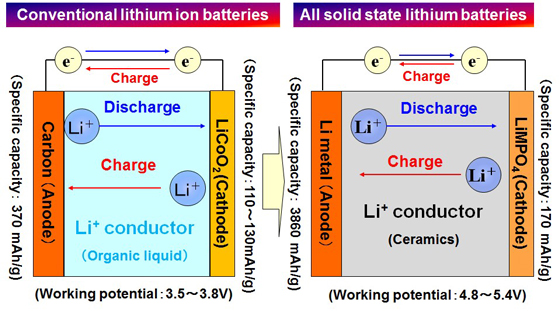

- Development of innovative rechargeable batteries (Fig. 11 )

- Development of novel cathode materials for high-capacity lithium ion batteries

- Development of novel process for synthesizing nanostructured spherical particles

- Microwave assisted hydrothermal synthesis of nanostructured particles

- Development of novel cathode materials for all solid state lithium batteries and novel synthesis processes

- Development of electrode materials for lithium sulfur batteries and novel synthesis processes

|

Fig. 11 Innovative rechargeable batteries.