|

|

|

|

|

|

|

|

|

|

|

|

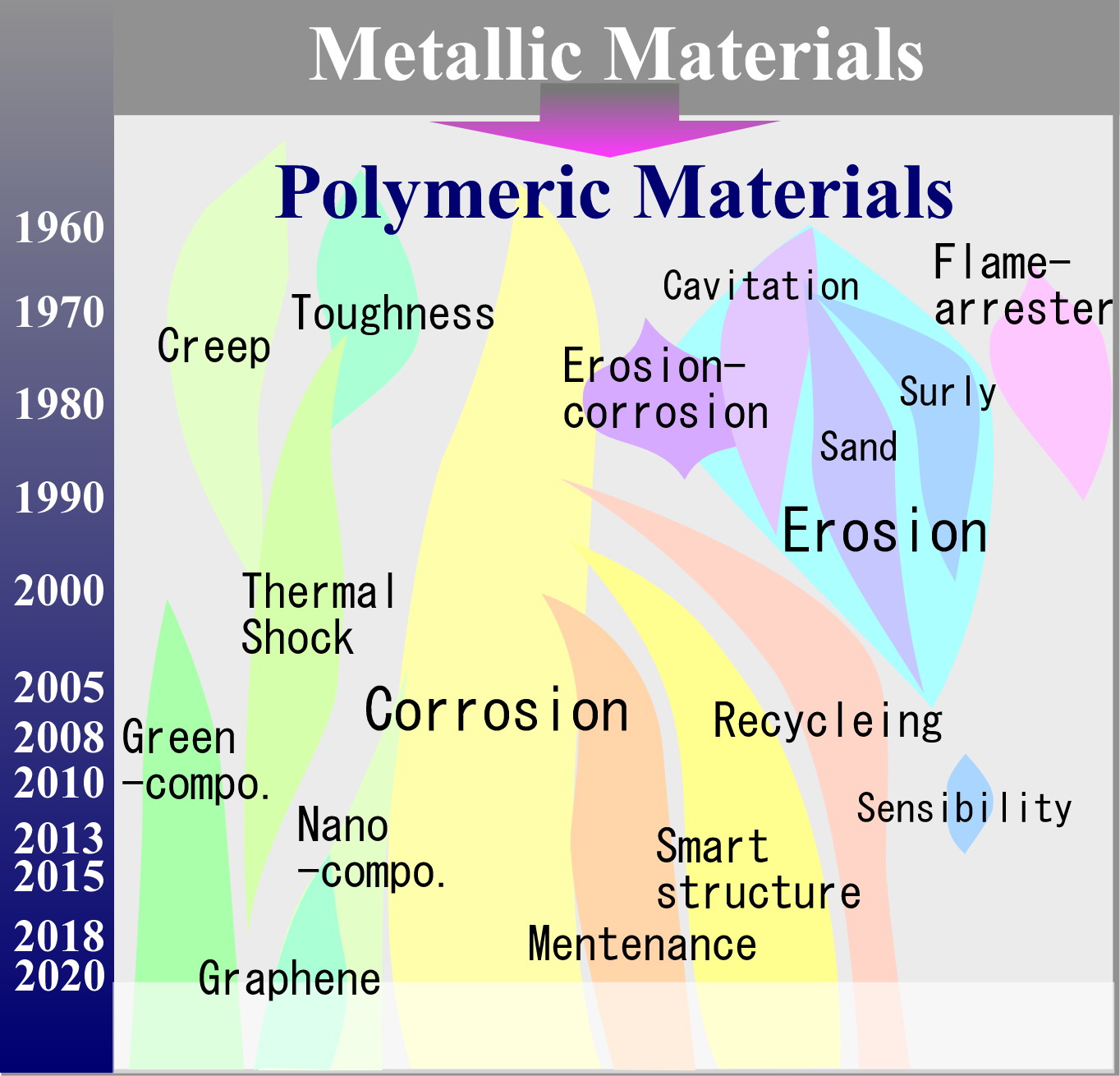

ResearchThe mission of our laboratory is to improve the durability of chemical engineering equipments. The flow of our research fields is shown in the figure below. We study on the fracture and degradation for polymeric materials and polymer composites, especially particle filled plastic composites. reserch abst. of 2018 Spring reserch abst. of 2018 Spring

Creep (terminated) Creep is one of the viscoelastic behaviors. Fiber reinforced plastic (FRP) is good for creep resistance. Thermal Shock Epoxy resin has been widely used in electric and electronic parts such as IC package because of its high electric insulation. However, thermal shock crack is observed by soldering. We try to improve the thermal shock resistance by filling hard and soft particles in epoxy resin (hybrid filler composites). Green Composites Natural souse material, especially composite using natural fiber is investigated. Nano-Composites Montmorillonite as a layered structure small filler, is used to make nano-composite when it is intercalated, exfoliated and dispersed in resin. Graphen is also taken from lyerd sturecture graphite. We found mass-production method of high-aspect-ratio few-layer-graphene by high-speed laminar flow. Recycling Thermosets are very difficult to recycle. We found that some chemical compounds selectively atack the chain bonds of crosslink in thermosets. We recover the corrosion products and try to recycle. Corrosion The term, corrosion, is defined as chemial degradation behavior of materials exposed in the corrosive environments such as acid, alkaline, organic solvent, and sea water. We study on the corrosion mechanisms of polymeric materials. Diffusion Control Diffusion is one of the important factors of the corrsion of plastics because corrosion rate depends on the magnitude correlation of diffusion and chemical reaction. So, we try to control the diffusion rate of environmental liquid into plastics. RBI/RBM Risk based inspection and Risk based maintenance for polymeric materials used in chemical plants should be studied. In case of FRP or organic materials, since effective NDT methods are needed to reduce a risk, UT and THz-TDS are studied. Smart Materials Recently, the technology of health monitoring and self-repairing is applied to materials and structures. These high performance materials are called SMART MATERIALS. We study on the evaluation of chemical degradation in plastics by using optical fiber. Sand Erosion (terminated) Erosion is the phenomenon in which materials are physically deteriorated resulting from the action of particles, drops and bubbles contained in the fluid. When particles=solid and fluid=gas, it is called sand erosion. A typical example is that a pipe may be eroded and damaged by the powders when they are delivered through the pipe. We study on the mechanisms of sand erosion behavior in plastics and its composites. Slurry Erosion (terminated) When particles=solid and fluid=liquid, the erosion is called slurry erosion. For example, the transportation of the coal powder and oil (or water) mixture may cause the damage of pipes. Computer simulations are carried out for the analysis of flow and particle motion in order to predict the erosion damage. Flame Arrester (terminated) Flame arrester is one of safety equipment in chemical plants. It prevents the fire from propagating in air-outlet pipes connected with oil tank. Flame arrester looks like a metallic wire gauze. The effects of the material properties, mesh dimension and flame propagation velocity on the performance of the flame arrester. |