Scope of Research

Scope of Research Recent Achievements

Recent Achievements Intensification of photo-induced oxidation processes by using micro-structured reaction spaces

Intensification of photo-induced oxidation processes by using micro-structured reaction spaces

Photo-induced oxidation processes are gathering attention as wastewater treatment technologies due to the emergence of new, specialized chemicals. However, these processes have some important drawbacks, such as low conversion of pollutants and costly light sources. In our research, we found that the use of channel microreactors led to an appreciable increase on photocatalytic conversion, while also saving capital and operational cost by allowing for the utilization of low-power light sources. The achieved reaction rates for the photocatalytic degradation of a model compound were orders of magnitude larger than the observed in conventional scale photoreactors. A significant contribution of surface phenomena to the performance of the microreactor was also seen. This research project led to the design, investigation and validation of two novel, low-cost micro-structured reactor concepts for applying with low-cost light sources and sunlight.

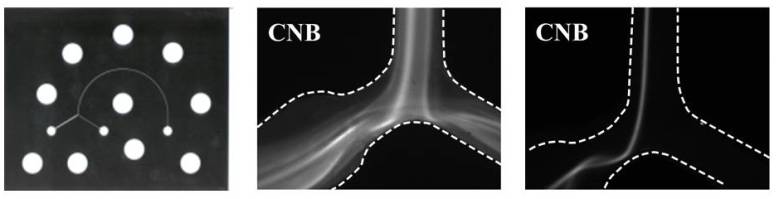

Micro-Separation

Micro-Separation

To attain drastic energy saving in the processes of phase separation, particle synthesis, environmental protection, and etc., a novel micro-separator is being developed by experimental and numerical approaches. The device shown in the left figure is composed of an arc-microchannel with a width of 200 microns, which is carved on stainless steel with a thickness of 150 microns by photo-etching. It has been confirmed that lift force due to steep shear rate in the arc-microchannel causes phase separation and, hence, density difference between phases is not required. Even for separating phases with small density difference, the device is found to attain 80 % energy saving compared to conventional hydrocyclone.

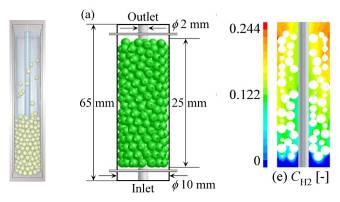

A High-Fidelity CFD Model of Methane Steam Reforming in a Packed Bed Reactor

A High-Fidelity CFD Model of Methane Steam Reforming in a Packed Bed Reactor

A novel CFD model is being developed to optimize design and operation of green processes. Hydrogen production in a packed bed reactor is modeled with a high-fidelity by means of DEM and CFD simulations. Based on the particle arrangement obtained by DEM simulation, CFD domain is automatically constituted by the developed method. The optimization will become possible based on the predicted distributions of gas species and temperature, which cannot be obtained by experiments.